Direct Metal Laser Sintering (DMLS) is an additive manufacturing process. Parts are built using a laser to selectively sinter (heat and fuse) a powdered metal material into layers.

The process begins once a 3D CAD file is mathematically sliced into multiple 2D cross sections and uploaded into the system. A ceramic blade pushes build material from a powder supply to create a uniform layer over a build piston platform. The laser scanning system literally draws the 2D cross section on the surface of the build material, sintering it into a solid form.

After the first layer is produced, the build piston is lowered and another powder layer is pushed into place using the ceramic blade, and the laser sinters the second layer. This process is repeated until the part is complete. Layer-by-layer manufacturing allows for the direct fabrication of complex parts that would be cost-prohibitive, and often impossible, to produce through traditional manufacturing processes.

WHAT DEFINES “PRODUCTION PARTS”?

The only difference between a prototype and a production part is that the production part meets all the characteristics specified by the design, including physical properties, dimensional tolerances, overall appearance, and cost requirements. A prototype part often involves compromises in one or more of these areas, particularly in physical properties.

While the DMLS process can be an effective prototyping tool, recent advancements in materials and process control have resulted in the fabrication of parts that are suitable for many production applications.

DMLS GENERAL TOLERANCES

Based on historical results (and application dependent) general tolerances for DMLS parts are ±0.005 inch for the first inch and ±0.002 inch per inch hereafter (±0.2 percent). The finish of DMLS parts as built are 350 Ra – µinch.

Note that geometry and part size impact the ability of the process to meet this guideline, and must be determined on a case-by-case basis.

If Stratasys Direct Manufacturing is informed of critical tolerances at the time of the RFQ submission, they are able to achieve tighter tolerances through a series of post processing methods they have learned over the years.

DESIGN GUIDELINES

Parts can be manufactured using DMLS in a variety of metal and alloy materials. Geometries remain fixed to a base plate during the building process via a support structure and are separated afterwards by breaking away the supports. It is not possible, however, to build detached parts, which can be done when making plastic laser sintered parts.

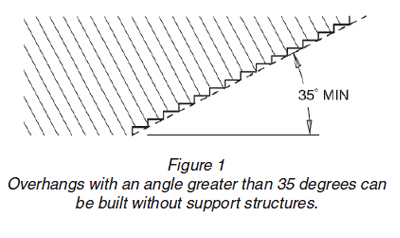

Overhangs with an angle greater than 35 degrees can be built without requiring a support structure. But, when supports are needed make sure that they are easy to access or else they cannot be removed in secondary operations.

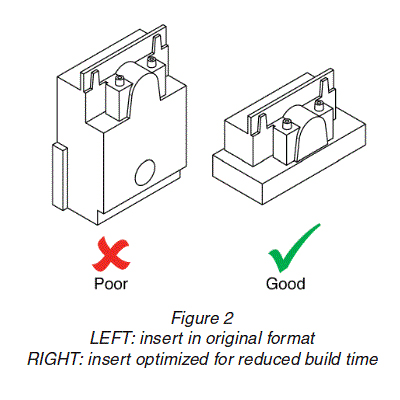

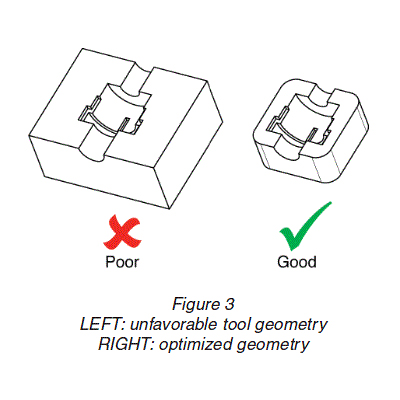

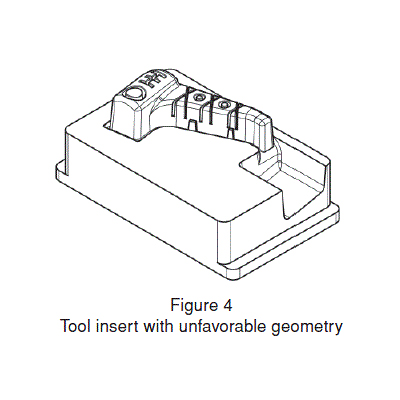

When working with DMLS, only relevant geometries should be built. Superfluous volumes should be avoided when using this technology. This is because build volume (the amount of material to be solidified), along with the number of layers is what determines the production time and costs, not the complexity of the geometry. For example, the tool insert displayed in the figure can be produced faster, and therefore more cost efficiently, if only the relevant geometry is built. The optimized version of the cavity, as shown, is also preferable for external corners to be round rather than sharp. Unnecessary volume has to be sintered with a longer build time and will be more expensive.

Overall, the most ideal geometries are small, self-supporting parts that would be difficult to manufacture through machining, are too expensive to investment cast, or are metal parts requiring short lead times.

SECONDARY SERVICE FOR FINISHING & POLISHING

HAND FINISHING

DMLS parts may have a raw finish, where surface roughness may be approximately 350 Ra – µinch or Ra – µmeter 8.75, or a medium turned surface. Our Basic hand finishing service includes support removal and some layer line and support structure artifact removal. At minimum, Basic finish is required for all DMLS parts. Our Premium hand finishing service removes all layer lines, supports and artifacts for a cleaner part. As with any rough surface, it can be improved up to 1 Ra – µinch or Ra – µmeter 0.025, which qualifies as a super mirror finish. To achieve the desired surface finish, consider media blasting, tumbling, hand polishing or secondary operations.

MEDIA BLASTING

Media Blasting is a surface treatment that forcibly propels a high-pressure stream of grit and ceramic material against the surface of the part to smooth it. First, the part is blasted with an aluminum oxide abrasive. This mattes the color and smooths the surface. Second, the part is glass bead blasted. The process provides a satin, matte finish of approximately 98 – 236 μinch Ra. The finish is largely uniform, but does not provide a 100 percent uniform finish.

TUMBLING

Tumbling can generate smooth exterior surfaces. This is a wet process that involves irregular ceramic media submersed in a surfactant. This composition is tumbled in a rotating barrel for 48 hours. The process results in a surface roughness between 32 and 124 μinch Ra, depending on the part geometry. Typical surface roughness is on the order of 65 μinch Ra.

HAND POLISHING

Hand Polishing is performed when projects have geometries in low quantities that are not tolerance dependent. These polishes are extremely cost effective, and provide a brilliant, highly-reflective finish.

For this option, engineers must consult with Stratasys Direct Manufacturing prior to building, because specific surfaces may need to be offset with additional material to ensure part integrity after post-processing. Note that optical polishing is not the ideal method for large batches because the finishes can be inconsistent from part to part.