The first step in the manufacturing process of any fastener, regardless of its final configuration, is cutting the bolt to length. Raw material in the form of round bar ranging from 12’ to 40’ in length is either saw cut or sheared. Cutting is the first step of the bolt manufacturing process.

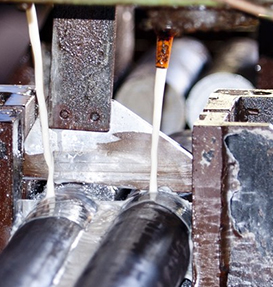

Bandsaws use saw blades to cut through the steel round bar. On the other hand, shearing equipment functions like a guillotine, “chopping” the raw material. During the shearing operation, the material is automatically run against a stop and then sheared to length. This lightning quick process is an extremely efficient method of cutting material and will translate into more cost effective product produced in a more time efficient manner.

Our capabilities include shear cutting and saw cutting.